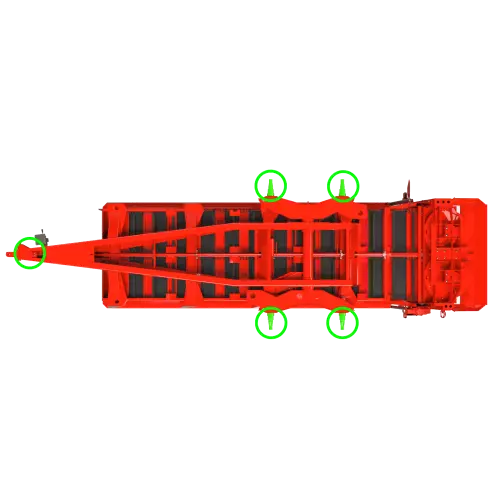

All-Steel, Welded Construction

An all-steel construction provides the backbone and solid framework for these spreaders. This simple, yet effective design keeps the sides and beater panels aligned for the life of the machine. The side of the box is constructed using 10-gauge steel, creating a seamless construction which reduces wear and increases protection against side rust through. The all-welded construction includes a reinforced tongue that pulls directly from the axle for added strength and durability.