Optimal crop pick up

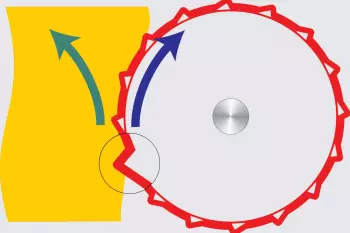

The cam-steered pick-up on the FB 3100 Series maximizes the full capacity of the machine. With a working width of 230 cm, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Straight pick-up tines help release the crop and reduce crop wrapping. Camless-shaped crop guides result in an efficient and gentle pick-up. A cam track pulls the tines straight down in the rearward position to avoid wrapping, making this the only hybrid pick-up on the market today. Therewith, it can handle every kind of crop, from long straw up to the shortest autumn silage or crops with fragaile leafs. The pick-up features standard pendulum frame and optional pivoting pick-up wheels to allow the pick-up to adapt to changing field conditions.

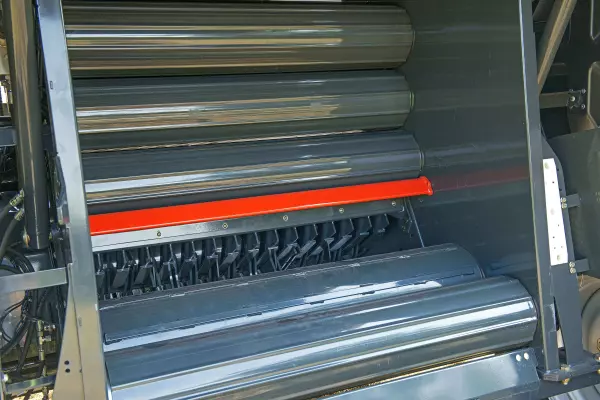

To better meet your operation's specific needs, there are two intake options available. Choose one of our INTEGRAL ROTORS – the non-cutting OPTIFEED rotor or the 14- or 23-knife OPTICUT cutting rotor.

To better meet your operation's specific needs, there are two intake options available. Choose one of our INTEGRAL ROTORS – the non-cutting OPTIFEED rotor or the 14- or 23-knife OPTICUT cutting rotor.