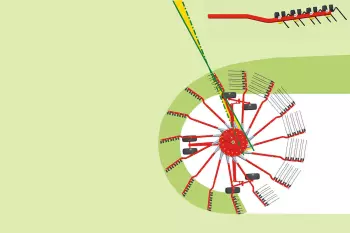

MASTERDRIVE GIII gearbox: reliable and wear-resistant

Today, farm machinery must work more and more hectares and withstand ever higher forces. Machine reliability and durability are the key to meet the requirements of users in terms of work output. The MASTERDRIVE GIII gearboxes have been developed to provide full protection of the drive components and improve wear resistance. This design ensures exceptional reliability and durability even for intensive use.

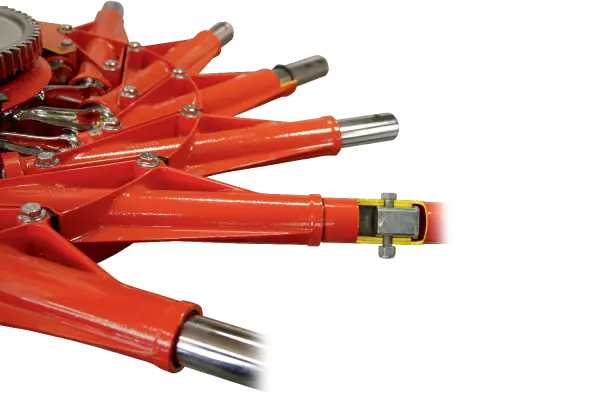

Inside, the MASTERDRIVE GIII includes a double reduction system with a bevel gear and a cylindrical gear. Bevel-reduction tolerances are tightly controlled making the system extremely reliable and robust, even in difficult conditions.

Gearbox wear is greatly reduced and no maintenance is required. The double reduction system makes it possible to include larger cylindrical gears with more teeth for better power transmission. A free wheel has been integrated in the gearbox to protect the inner components

Inside, the MASTERDRIVE GIII includes a double reduction system with a bevel gear and a cylindrical gear. Bevel-reduction tolerances are tightly controlled making the system extremely reliable and robust, even in difficult conditions.

Gearbox wear is greatly reduced and no maintenance is required. The double reduction system makes it possible to include larger cylindrical gears with more teeth for better power transmission. A free wheel has been integrated in the gearbox to protect the inner components