MASTERDRIVE GIII gearbox: reliable and wear-resistant

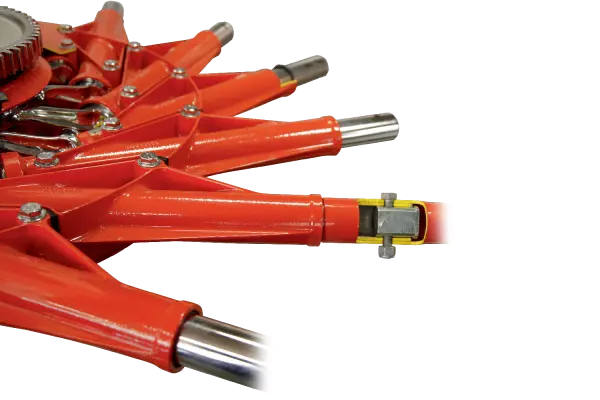

Agricultural machines have to withstand increasing amounts of pressure and larger working areas today. The reliability and longevity of machines is key to meeting the demands of farmers and satisfying their output needs. MASTERDRIVE GIII gearboxes are fully enclosed. Result: total protection of drive parts that are less subject to wear. Their design ensures exceptional reliability and longevity, even under intensive use.

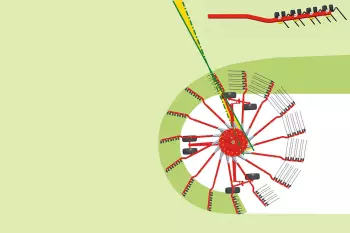

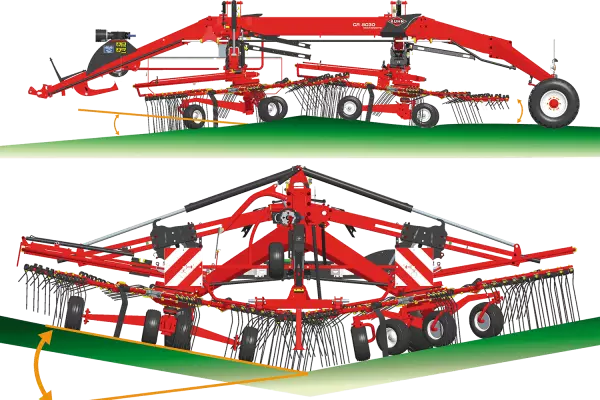

The four rakes are equipped with equipped with the MASTERDRIVE rotor which is well known for its reliable design and exceptional longevity, even when used intensively.

It includes a double reduction gearbox system with a bevel gear and a cylindrical gear. Bevel reduction tolerances are tightly controlled making the system extremely reliable and robust, even in difficult conditions.

Gearbox wear is greatly reduced and no maintenance is required. The double reduction gearbox system makes it possible to include larger cylindrical gears with more teeth for better power transmission.

The four rakes are equipped with equipped with the MASTERDRIVE rotor which is well known for its reliable design and exceptional longevity, even when used intensively.

It includes a double reduction gearbox system with a bevel gear and a cylindrical gear. Bevel reduction tolerances are tightly controlled making the system extremely reliable and robust, even in difficult conditions.

Gearbox wear is greatly reduced and no maintenance is required. The double reduction gearbox system makes it possible to include larger cylindrical gears with more teeth for better power transmission.