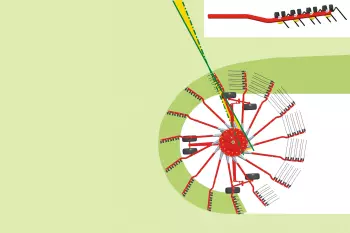

A versatile rake

Raking width is hydraulically adjustable from 3.00 to 5.80 m, therfore varying forage densities, bypassing obstacles and finishing off fields are no longer a problem. For very dense forage and for producing swaths at night, the GA 6002 can also deliver two swaths from each pass.