EXCLUSIVE: LIFT-CONTROL and NON-STOP safety combined

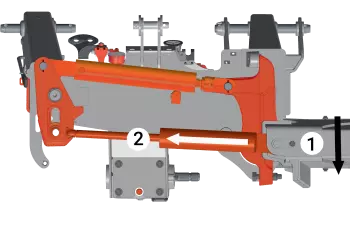

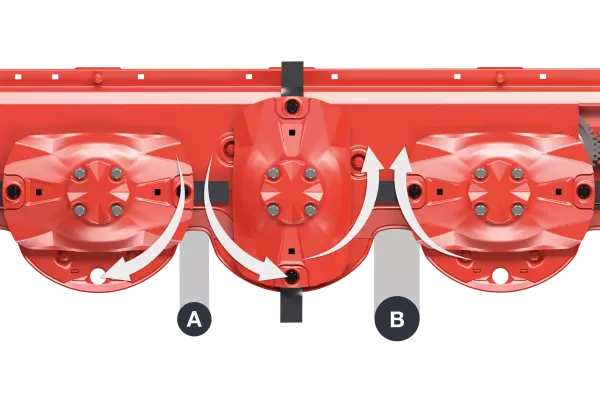

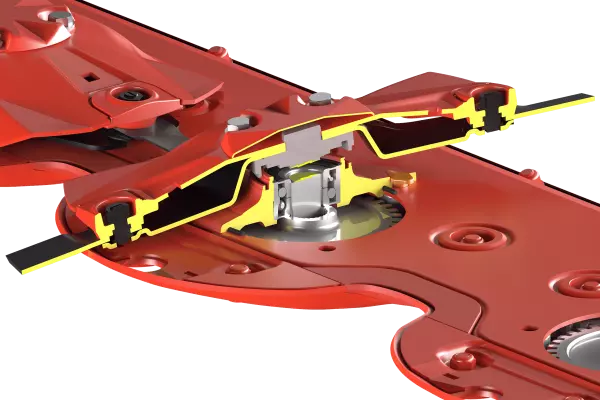

No farmer can allow their mower to get damaged mid-season by hitting an obstacle or a wrong manouvere. These mowers are equipped with an active system that ensures constant ground pressure, up to an angle of 11°. Should the unit come into contact with an obstacle, ground pressure is reduced and the mower unit pivots up to 25 degrees to the rear and passes over the obstacle. The active Non-Stop breakaway system is also effective when the cutter bar is impacted on the left as the arm's pivot point is far enough away from the first discs (A). The mower unit returns to its initial work position automatically with the NON-STOP system. The suspension and NON-STOP safety system combination of this machine is unique in the market.