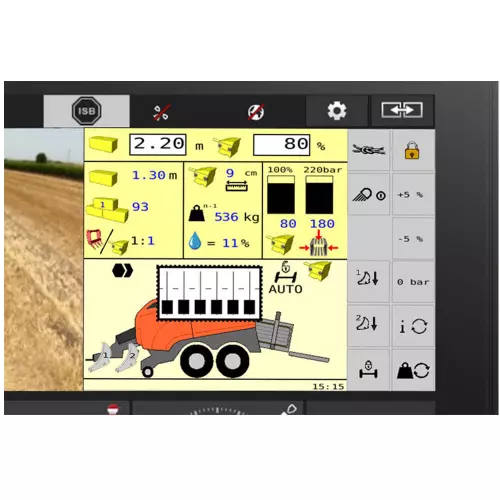

POWER DENSITY - The KUHN Solution

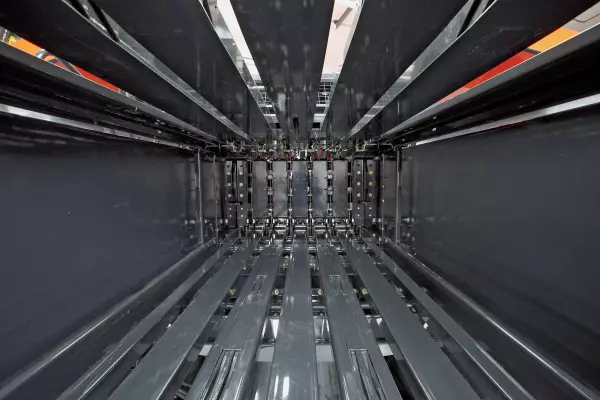

Consistently shaped bales provide more than just aesthetic appeal. A dense, consistently filled bale represents quality in every form. Square bales are easy to handle and stack. In addition, they are much more stable during transport than a poorly formed bale. A perfect square-edged bale reduces the risk of air entrapment during wrapping. This stimulates conservation of the bale and ensures a better feed quality.

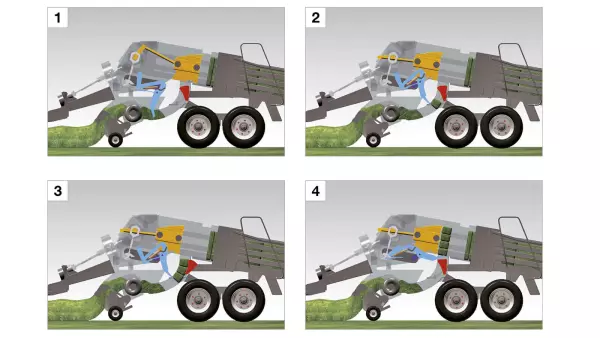

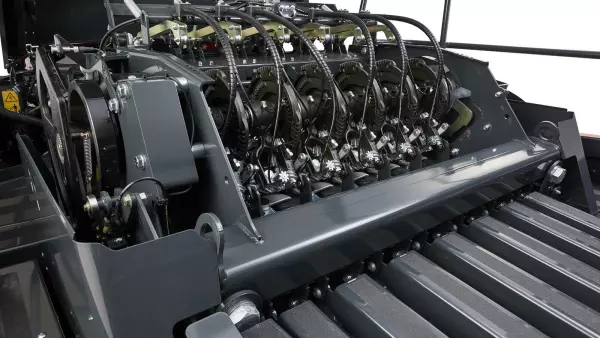

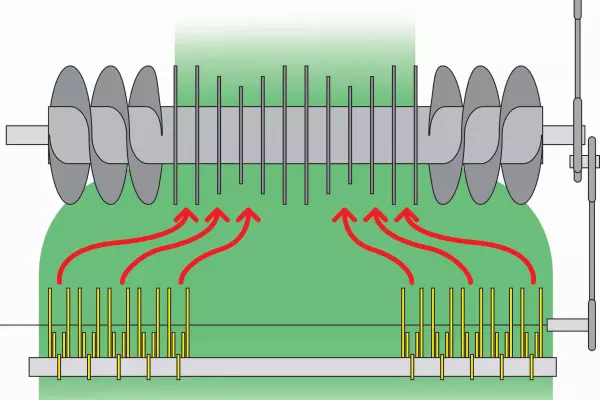

The KUHN POWER DENSITY system, a single feeder fork design, proves that a well-engineered active pre-chamber filling system can eliminate complexity. This pre-chamber system ensures consistently filled flakes and results in heavy, square-edged bales regardless of the swath condition. The single feeder fork combines two functions into one mechanism, eliminating unneeded components and complexity and resulting in lower maintenance cost.

The KUHN POWER DENSITY system, a single feeder fork design, proves that a well-engineered active pre-chamber filling system can eliminate complexity. This pre-chamber system ensures consistently filled flakes and results in heavy, square-edged bales regardless of the swath condition. The single feeder fork combines two functions into one mechanism, eliminating unneeded components and complexity and resulting in lower maintenance cost.