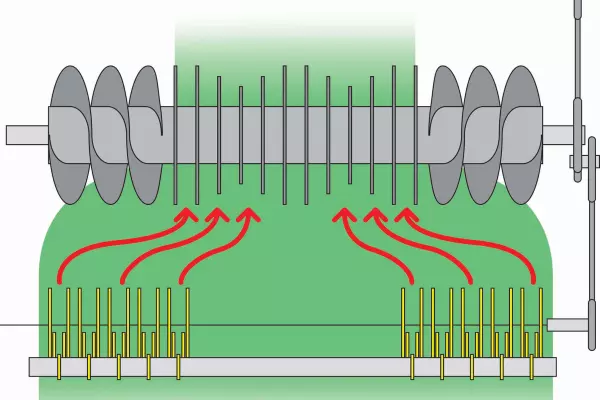

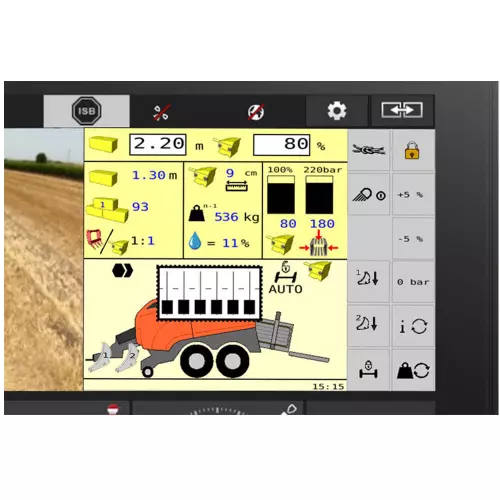

One plunger stroke - double impact

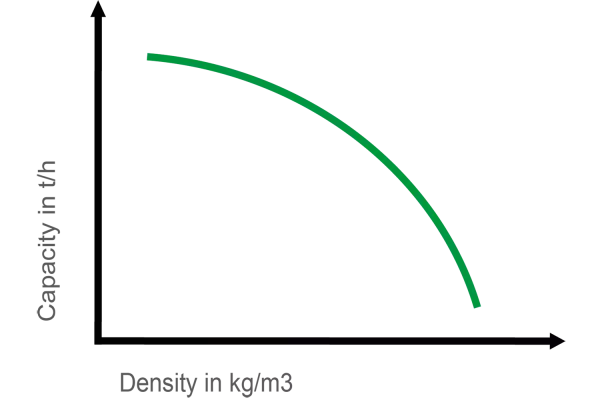

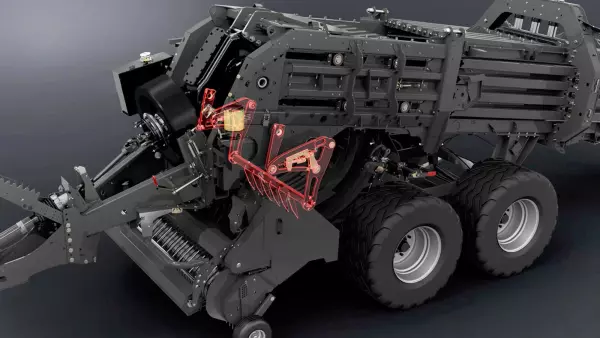

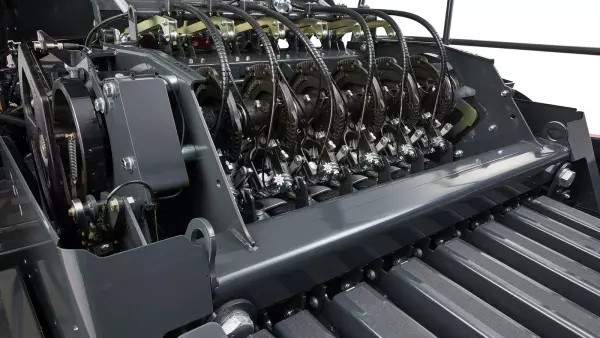

The KUHN SB 1290 iD features the patented TWINPACT double plunger system, an intelligent way to reach extremely high bale densities and avoid high peak loads on the machine. To achieve up to 25% higher bale density, the plunger requires twice the force of a conventional large square baler. The TWINPACT plunger is divided into an upper and lower part, which are connected with a triangle rod. The plunger impact on the bale is divided into two steps, increasing the applied force per surface area and thus bale compaction. Despite the heavier bales, the load on the machine is comparable with a conventional 120 x 90 baler, eliminating the need for an oversized driveline, flywheel and main frame.

The TWINPACT effect:

The TWINPACT effect:

- Ensures intelligent, efficient bale compaction whilst avoiding high peak loads on the machine.

- Gives you the possibility to work with similar tractor sizes as with conventional 120 x 90 balers.

- Produces bales that are 25% heavier in dry crop conditions.