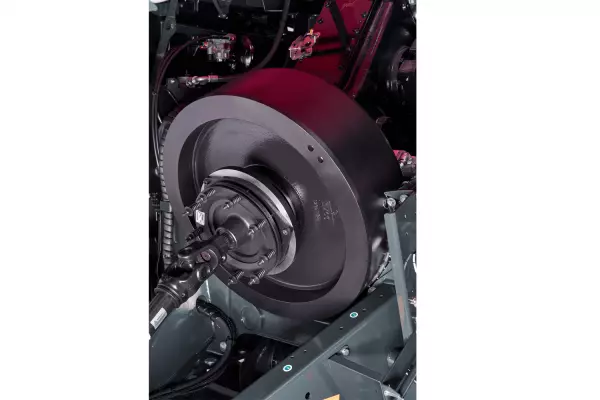

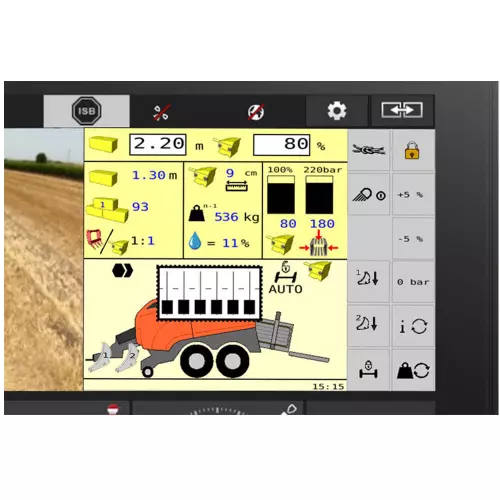

A perfect balance between capacity and density

The KUHN patented torque regulation system on all SB 120 cm bale channel models ensures a perfect balance between capacity and density. The system consists of plunger rod load pins that measure the plunger force and an angle sensor that measures the crank angle. Throughout the complete plunger cycle the exact torque is calculated so you can operate the machine at peak performance and achieve the hightest bale density. This results in a higher transport and handling efficiency.