Optimal crop pick-up

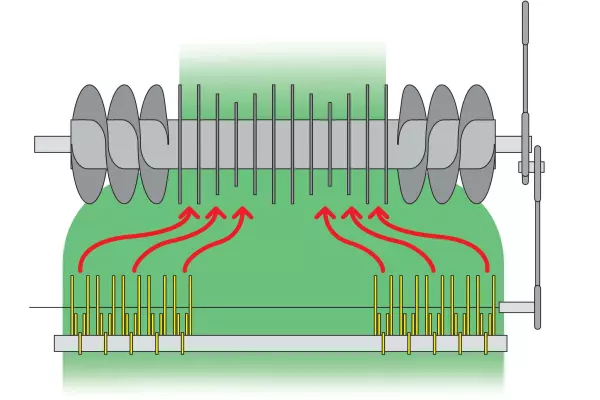

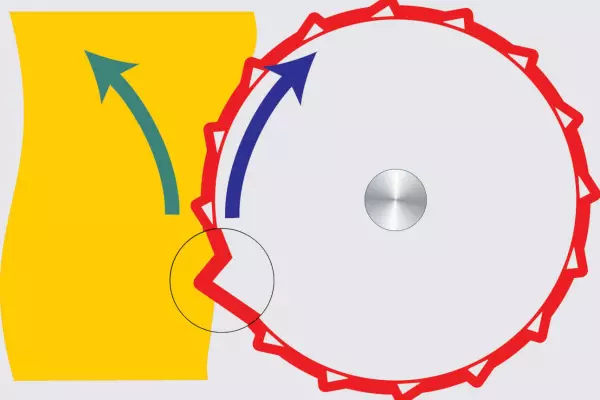

The pick-up on the i-BIO+ maximises the full capacity of the machine. With a working width of 230 cm, the machine is capable of working in all swaths and will not let you down, even in the toughest conditions. Straight pick-up tines help release the crop from the ground and reduce crop wrapping. Camless-shaped crop guides result in a more aggressive and efficient pick up. A cam track pulls the tines straight down in the rearward position to avoid wrapping, making this the only hybrid pick-up on the market today. As standard, the pick-up features a pendulum frame and optional pivoting pick-up wheels to allow the pick-up to adapt to changing field conditions.

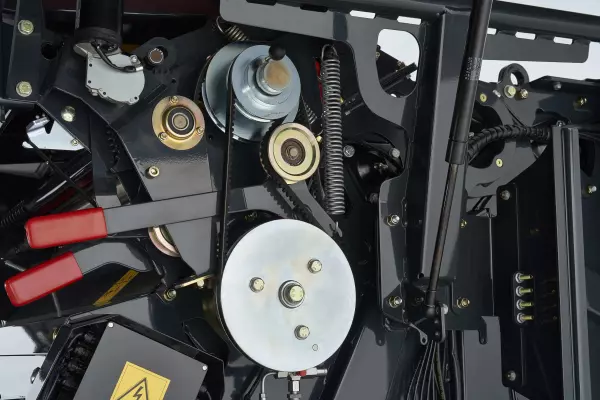

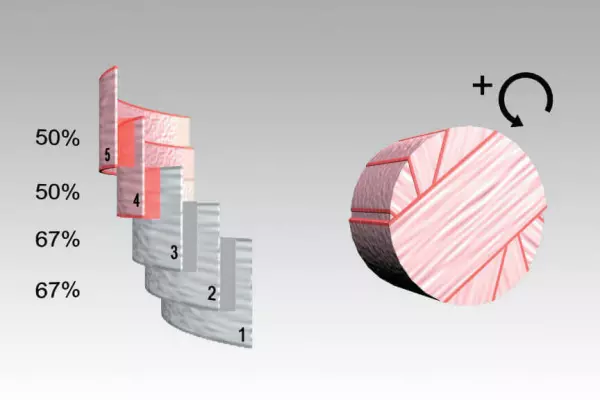

Choose one of our INTEGRAL ROTORS: the 14- knife or 23-knife OPTICUT cutting rotor.

Choose one of our INTEGRAL ROTORS: the 14- knife or 23-knife OPTICUT cutting rotor.