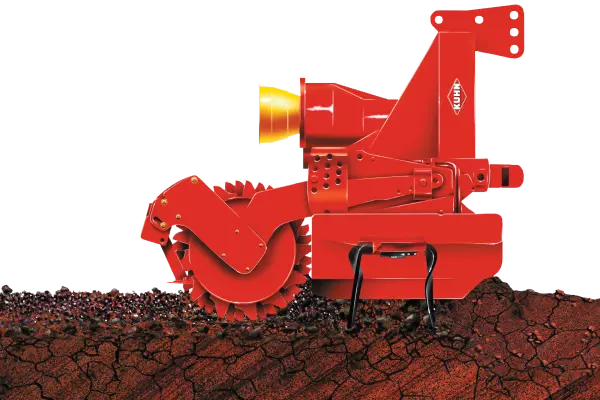

A rotor sometimes copied never matched

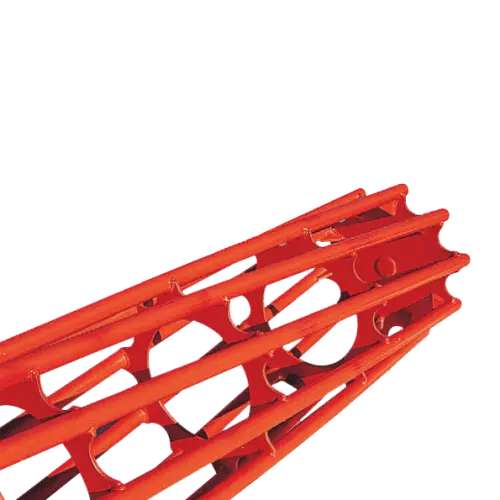

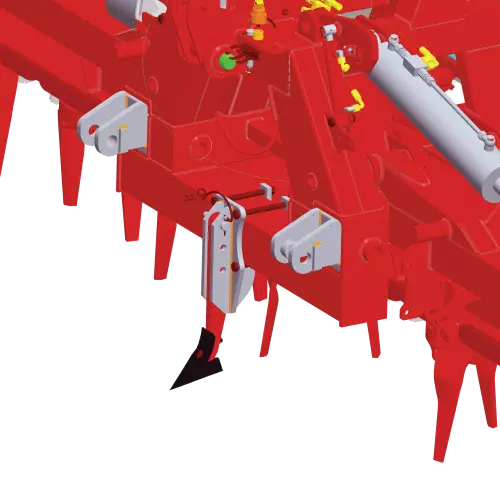

The powerful rotor drive is fully protected by a rigid gearbox and trough. The casing, bearings and tine holders form a compact and very sturdy assembly, limiting the torsion stress on the casing. The rotor has a high-rigidity, maintenance-free trough. The curved profile of the forged steel sprockets ensure that the gears are in line with the upper bearings. The maintenance free bearings create a permanent hold, eliminating any risk of play. The sealing is reinforced by a cassette seal on the HR and a lip seal on the HRB. The conical centering of the blade holder (KUHN patent) eliminates any risk of play in the splines. The blade holder is oval-shaped, avoiding blockages of stones and encouraging their evacuation.