A design conceived to save you time

The models of the VARI-LEADER range have been designed to make your work easier:

- the turning radius of 110° allows the reduced size headlands to be created;

- a significant distance between the stem and the first point allows you to work without risk of tractor damage even in the shortest U-turns. This means less fatigue and more serenity at work.

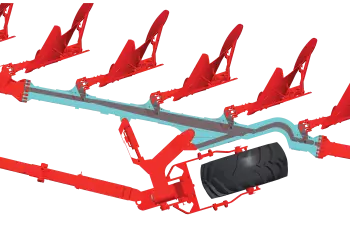

- the number of distributors to operate during U-turns is reduced thanks to a hydraulic sequence fitted as standard throughout the range.

- optimal comfort thanks to a gradual U turn. U-turns are done smoothly by two single-acting telescopic cylinders. Pressure on the lift arms of the tractor is reduced.