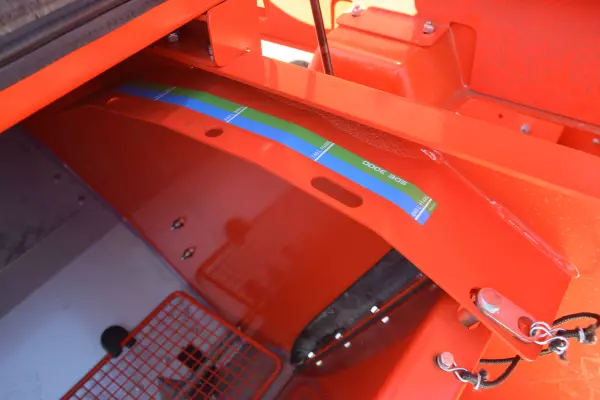

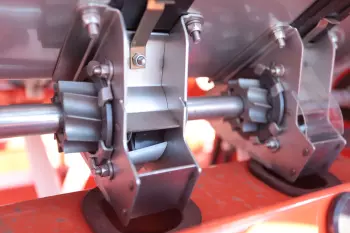

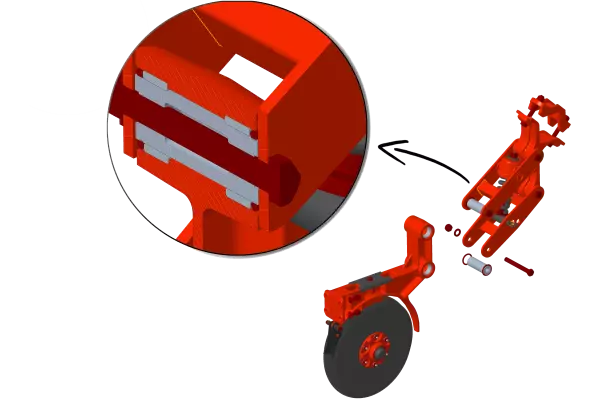

Helica metering unit

The Helica metering unit is an exclusive KUHN seed drill feature. Designed to achieve maximum precision with robustness and durability.

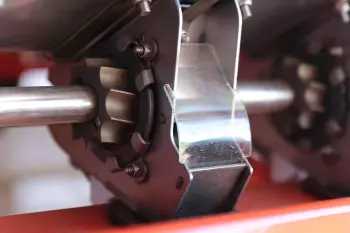

The helical roller is able to distribute fertilizer homogeneously with any grain size and seeds of all sizes and shapes. More efficient than common metering units, the Helica ensures precise and even application rates with low coefficient of variation from row to row, even on hilly conditions, and is not affected by vibrations.

Manufactured in stainless steel and polymers of high quality, the Helica is wear resistant for a long service life and low maintenance.

The helical roller is able to distribute fertilizer homogeneously with any grain size and seeds of all sizes and shapes. More efficient than common metering units, the Helica ensures precise and even application rates with low coefficient of variation from row to row, even on hilly conditions, and is not affected by vibrations.

Manufactured in stainless steel and polymers of high quality, the Helica is wear resistant for a long service life and low maintenance.