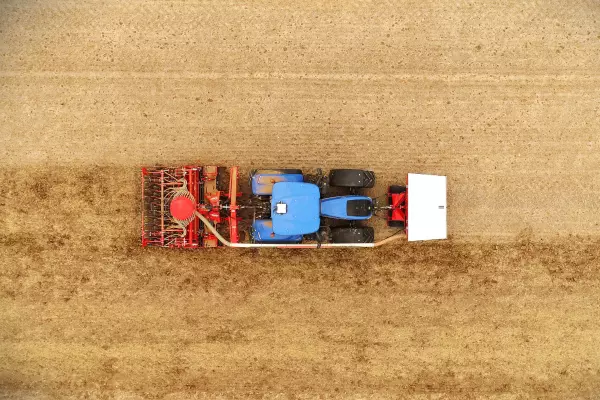

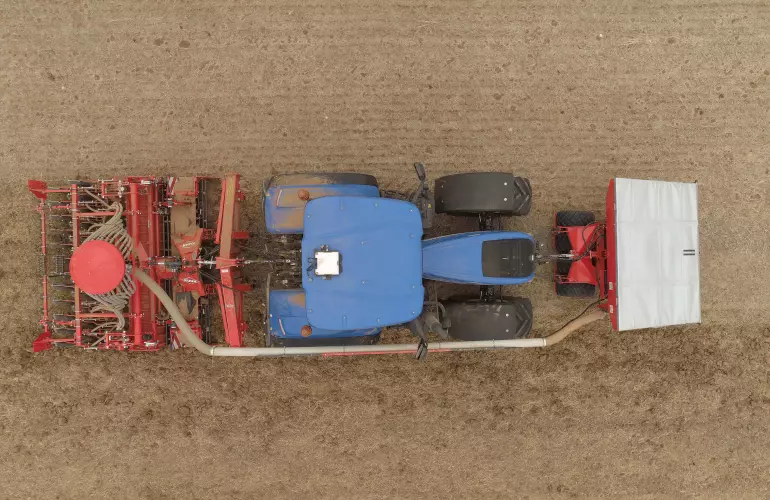

VENTA metering system, precise and reliable

The VENTA metering system with volumetric flutes, distributes seeds, fertiliser and cover crops with no additional equipment required. All central components are in stainless steel. No tools or disassembly is necessary for maintenance.

Equipped with an electric drive system, application rate can be adjusted while working, either manually or via an Variable Rate Application map.

Equipped with an electric drive system, application rate can be adjusted while working, either manually or via an Variable Rate Application map.