| 12 to 36 (depending on discs and product to spread) | 12 to 36 (depending on discs and product to spread) | 12 to 36 (depending on discs and product to spread) | 12 to 36 (depending on discs and product to spread) | 12 to 42 (depending on discs and product to spread) | 12 to 42 (depending on discs and product to spread) | 12 to 42 (depending on discs and product to spread) | 12 to 42 (depending on discs and product to spread) | 12 to 42 (depending on discs and product to spread) | 18 to 50 (depending on discs and product to spread) | 12 to 50 (depending on discs and product to spread) |

| 1000 / 2300 | 1000 / 2300 | 1000 / 2300 | 1000 / 2300 | 1400 / 3200 | 1400 / 3200 | 1400 / 3200 | 1400 / 3200 | 1400 / 3200 | 3200 or 4200 | 3200 or 4200 |

| 2300 | 2300 | 2300 | 2300 | 3200 | 3200 | 3200 | 3200 | 3200 | 4200 | 4200 |

| 95 | 95 | 95 | 95 | 106 | 106 | 106 | 106 | 106 | 176 (4200l) | 176 (4200l) |

| 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.40 or 2.80 depending on extension | 2.90 | 2.90 |

| 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.30 or 2.70 depending on extension | 2.80 | 2.80 |

| 400 or 6.66 | 400 or 6.66 | 400 or 6.66 | 400 or 6.66 | 500 or 8.33 | 500 or 8.33 | 500 or 8.33 | 500 or 8.33 | 500 or 8.33 | 500 or 8.33 | 500 or 8.33 |

| assisted by the QUANTRON A | | | | assisted by the QUANTRON A | | | | | |

| Chute + graduated plate as standard + DFC proportional graduation | Chute + graduated plate as standard + DFC proportional graduation | | | Chute + graduated plate as standard + DFC proportional graduation | Chute + graduated plate as standard + DFC proportional graduation | | | | | |

| Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Manual modification of the drop point on the disc | Modification of the drop point on the disc from the cab | Modification of the drop point on the disc + disc speed from the cab | Modification of the drop point on the disc from the cab | Modification of the drop point on the disc + disc speed from the cab |

| Manual | Manual | Manual | Manual | Manual | Manual | Manual | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive |

Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset | Fertiliser identification guide

Spreading charts available on www.kuhn.com "Services" and the mobile app Spreadset |

| From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading | From the mobile app Spreadset + the Wifi module (as option)

With the weighing frame: display on the Smartphone of the quantity remaining in the hopper when loading |

| Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - electric drive - without maintenance | Ultra-slow rotation: 17 min-1 - without maintenance | Ultra-slow rotation: 17 min-1 - electric drive - without maintenance |

| Hydraulic (2 DA) | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | Hydraulic (2 DA) | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive | SpeedServo: motors with high-speed drive |

| | Weighing frame - regulation every second | EMC system on each disc - Independent left/right regulation every second | | | Weighing frame - regulation every second | EMC system on each disc - Independent left/right regulation every second | EMC system on each disc - Independent left/right regulation every second | EMC system on each disc - Independent left/right regulation every second | EMC system on each disc - Independent left/right regulation every second |

| | | TC-SC, TC-GEO and TC-BAS as standard on machine side | | | | TC-SC, TC-GEO and TC-BAS as standard on machine side | TC-SC, TC-GEO and TC-BAS as standard on machine side | TC-SC, TC-GEO and TC-BAS as standard on machine side | TC-SC, TC-GEO and TC-BAS as standard on machine side |

| Without terminal | QUANTRON A with colour display | | ISOBUS CCI terminal or use of ISOBUS tractor terminal | Without terminal | QUANTRON A with colour display | | ISOBUS CCI terminal or use of ISOBUS tractor terminal | ISOBUS CCI terminal or use of ISOBUS tractor terminal | ISOBUS CCI terminal or use of ISOBUS tractor terminal | ISOBUS CCI terminal or use of ISOBUS tractor terminal |

| | | As standard with CCI 1200 | | | | As standard with CCI 1200 | As standard with CCI 1200 | As standard with CCI 1200 | As standard with CCI 1200 |

| As standard | As standard | As standard | | As standard | As standard | As standard | As standard | As standard | As standard |

| As standard | As standard | As standard with CCI terminal | | As standard | As standard | As standard with CCI terminal | As standard with CCI terminal | As standard with CCI terminal | As standard with CCI terminal |

| As standard | As standard | As standard | | As standard | As standard | As standard | As standard | As standard | As standard |

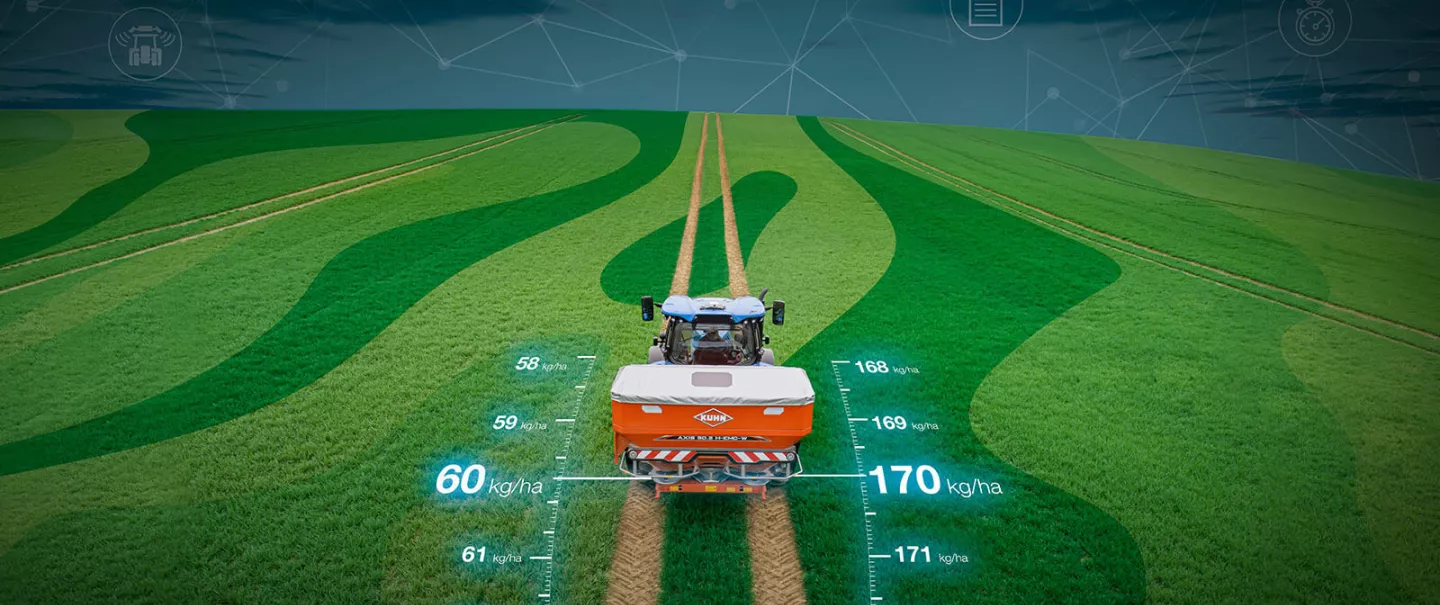

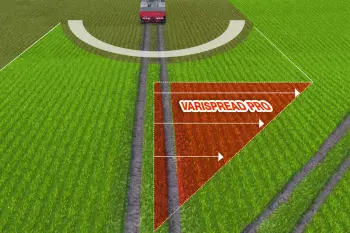

| VariSpread 8 (8 sections, 4 by side) per quantity reduction | VariSpread 8 (8 sections, 4 by side) per quantity reduction | VariSpread 8 (8 sections, 4 by side) per quantity reduction | | VariSpread 8 (8 sections, 4 by side) per quantity reduction | VariSpread 8 (8 sections, 4 by side) per quantity reduction | VariSpread PRO (by modifying the drop point and continuous quantity reduction at very high speed) | VariSpread PRO (Modification of the drop point, disc speed and continuous quantity reduction at very high speed) | VariSpread PRO (by modifying the drop point and continuous quantity reduction at very high speed) | VariSpread PRO (Modification of the drop point, disc speed and continuous quantity reduction at very high speed) |

| | As standard, for the regulation every second | | | | As standard, for the regulation every second | | As standard - to monitor the remaining quantity of fertiliser in the hopper | As standard - to monitor the remaining quantity of fertiliser in the hopper | As standard - to monitor the remaining quantity of fertiliser in the hopper |

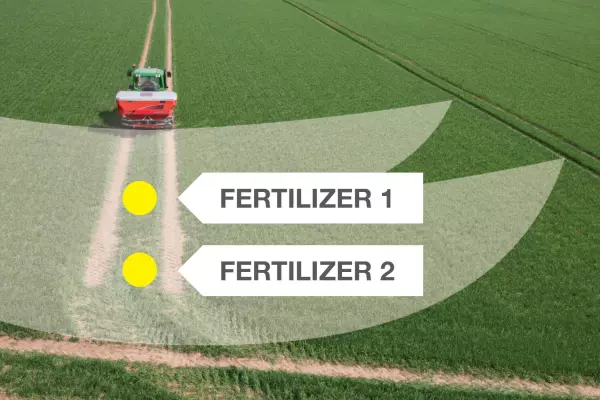

| | | | | | | | As standard - To left and/or right by reducing the disc speed and drop point | | As standard - To left and/or right by reducing the disc speed and drop point |

| As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard |

| As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard |

| As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) | As standard - with fast removal (1/4 turn) |

| Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 2 | Yokes with 2 height positions - Cat. 3 | Yokes with 2 height positions - Cat. 3 |

| Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Without maintenance - drive : 540 to 650 | Hydraulic | Without maintenance - drive : 750 to 900 | Hydraulic |

| | | | | | | | | As standard on left side - optional on right side | As standard on left side - optional on right side |

| | | | | | | | 1x pressure + 1x free return (with or without load sensing) | | 1x pressure + 1x free return (with or without load sensing) |

| | | | | | | | 45 l/min at 180 bars | | 65 l/min at 180 bars |

| 295 | 295 | 447 | 397 | 327 | 327 | 347 | 347 | 447 | 730 | 780 |