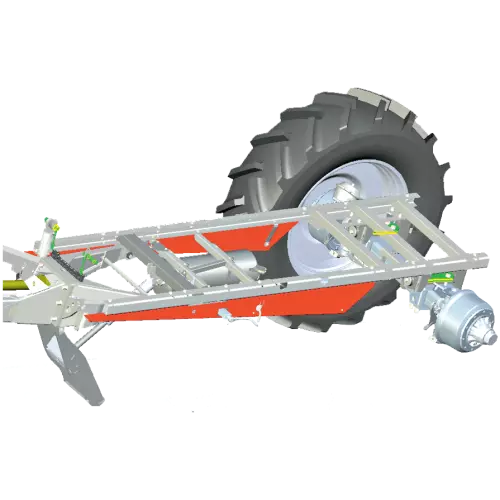

The only trailed machine with continuous EMC "weighing" on each disc."

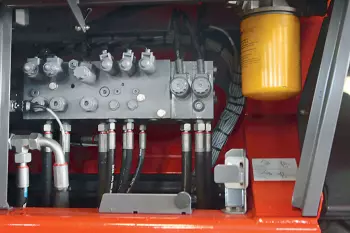

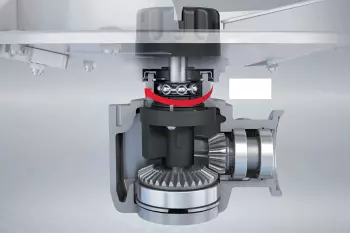

EMC (Electronic Mass Control) adjusts the application rate, left and right, every second independently, like a "weighing" device on each disc. This unique system by KUHN allows every plant to receive the right dose of fertiliser every second. It's simple, fertiliser flow is measured on each disc: in the event of clogging or blockage, the flow rate of the outlet concerned is corrected immediately and automatically!

For over 20 years, you have been spreading the right application rate in the right place because you get the right fertiliser flow at each outlet.

Sensors read the drive torque at each disc every second. Depending on the reading, the flow rate is adjusted automatically and separately on the left and right-hand discs.

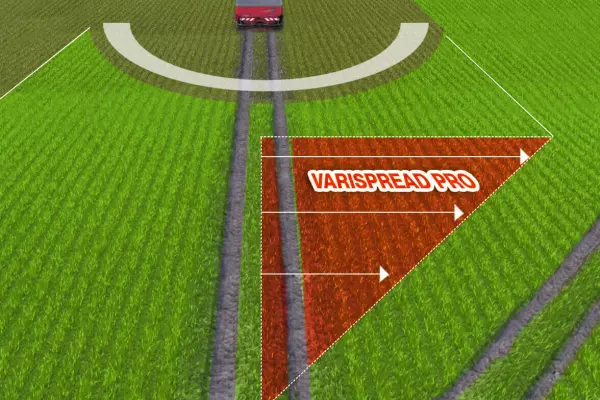

With EMC, you adjust left and right flow rates individually without feeling the effects of slopes and vibrations. You are also more fuel efficient due to the lower motor speed. There is no need to do a flow test, just enter the application rate and start spreading. Flow rate possibilities are large: between 20 and 500 kg/min, so left/right application rate adjustment by GPS is possible with extreme precision.

For over 20 years, you have been spreading the right application rate in the right place because you get the right fertiliser flow at each outlet.

Sensors read the drive torque at each disc every second. Depending on the reading, the flow rate is adjusted automatically and separately on the left and right-hand discs.

With EMC, you adjust left and right flow rates individually without feeling the effects of slopes and vibrations. You are also more fuel efficient due to the lower motor speed. There is no need to do a flow test, just enter the application rate and start spreading. Flow rate possibilities are large: between 20 and 500 kg/min, so left/right application rate adjustment by GPS is possible with extreme precision.